Customer Designed Parts

SMG’s Contract Manufacturing division specializes in supplying customer designed parts and assemblies. We offer a comprehensive supply program that has been supporting U.S. and Canadian manufacturers for more than 20 years. It is designed to ensure that parts are priced competitively, meet your specifications, and delivered on time.

WE CAN HELP YOU BY:

Reducing unit costs on existing parts

Improving existing part quality

Increasing inventory turns by stocking in the U.S. or Canada and introducing JIT supply

Quoting a new part design

Ensuring your part is designed for ideal manufacturability

Reducing tariff exposure by relocating production to another country such as India or Vietnam

Supplying parts under USMCA with 0% tariff

Our comprehensive supply program includes:

Tooling Development

We create the molds and fixtures necessary to produce your part and maintain them throughout the lifetime of our supply

Sample Submission

We provide a Level 2 or 3 PPAP based on your request

Mass Production

We manufacture your parts through our global manufacturing network to ensure you get the most competitive price

Quality Assurance and Control

Our in-country quality teams make certain that parts are produced to your requirements

Logistics and Warehousing

We manage material movement from the country of origin to a local SMG fulfilment center

JIT Inventory Management

We hold stock of your parts and release shipments to you on an as needed basis

As a customer, you will be quoted a unit cost and any tooling necessary to produce your part. The unit cost is based on our comprehensive supply program which includes all freight and applicable customs charges to SMG’s warehouse in the U.S. or Canada. Upon request, we can offer you a landed unit cost, inclusive of domestic freight charges to your facility.

We Specialize In:

Low to medium volume manufacturers and industrial producers

We supply in the hundreds and thousands per year

Parts and assemblies that are specific to you

Designed and engineered for your application, we are not an off-the-shelf reseller

Global Manufacturing

Our supply comes from India, Mexico, SE Asia (Vietnam, Malaysia, Thailand), Taiwan and China

Inventory Management in the USA and Canada

We hold inventory of your parts and release based on your schedule

What do we need from you to provide a quote?

We Require:

- Part drawing and/or sample

- Quantity you consume per year

- How frequently do you want to receive deliveries

- Are there any issues related to the existing part supply that we should be aware of

- Quality from current supplier, poor delivery performance, etc.

Optional information:

- CAD model in stp, step, or SolidWorks format

OUR SUPPLY CATEGORIES

Casting, Die Casting, Forgings

Electronic Industrial Assemblies

Extrusions

Metal Fabrications

Machined Parts

Plastic Molded and Formed

Rubber Molded and Formed

Stampings

COMMITMENT TO QUALITY

Our dedication to quality from the time of RFQ to the receipt of goods to your facility is the foundation that sets us apart. It starts with our New Product Introduction (NPI) process. The NPI team works together with our customers to understand the critical requirements of each part and the related materials and processes. We use these inputs to work closely with our manufacturing partners to define and deploy controls and verification criteria to reduce process variation and achieve defect-free and on-time production.

Every part that is supplied by SMG goes through our Quality team using an AQL sampling plan before being released for shipment to North America. Our SMG Quality team members are full-time, in-country employees who use and enforce the controls and verification criteria defined during the New Production Introduction stage. These inspection activities are in addition to the quality inspections completed by our manufacturing partners.

We don’t leave anything to chance —once the goods reach North America, another incoming inspection based on AQL sampling is completed before released for shipment. Inspection data is collected through our multiple inspection points to predict future potential issues through trend analysis, further reducing risks for customers.

QUALIFICATIONS

Click the logo to review the certificate

In progress

In progress

Estimated completion date of Q3 2025

Contact us to request our 2024 FHR

In progress

Estimated completion date of Q2 2026

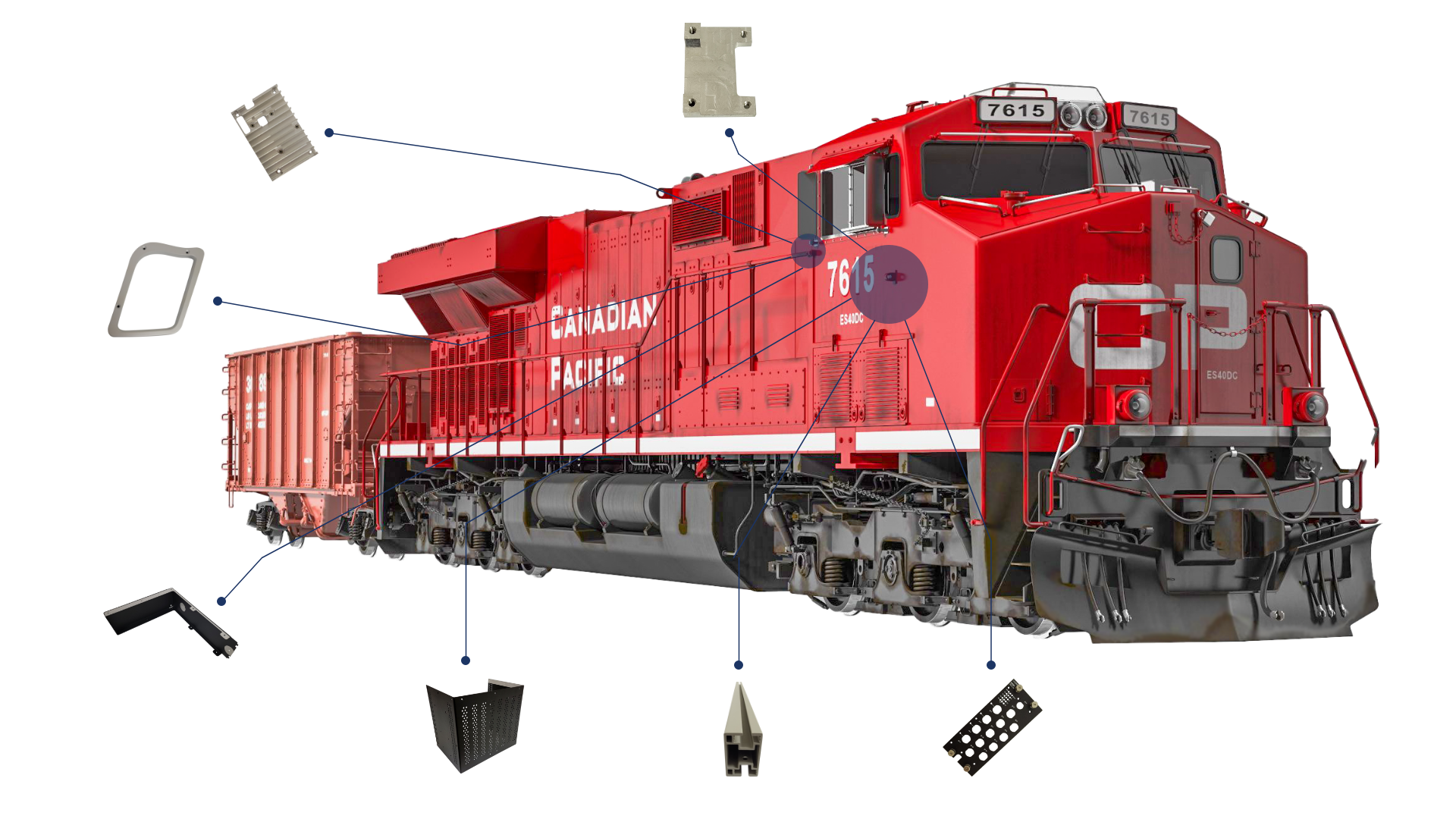

Parts In Supply

Click the vehicle to the see parts in detail

Industries Served

General industrial

Transportation

Heavy equipment

Material Handling

Agriculture Equipment

Power Equipment

Clean Technology

Telecommunications

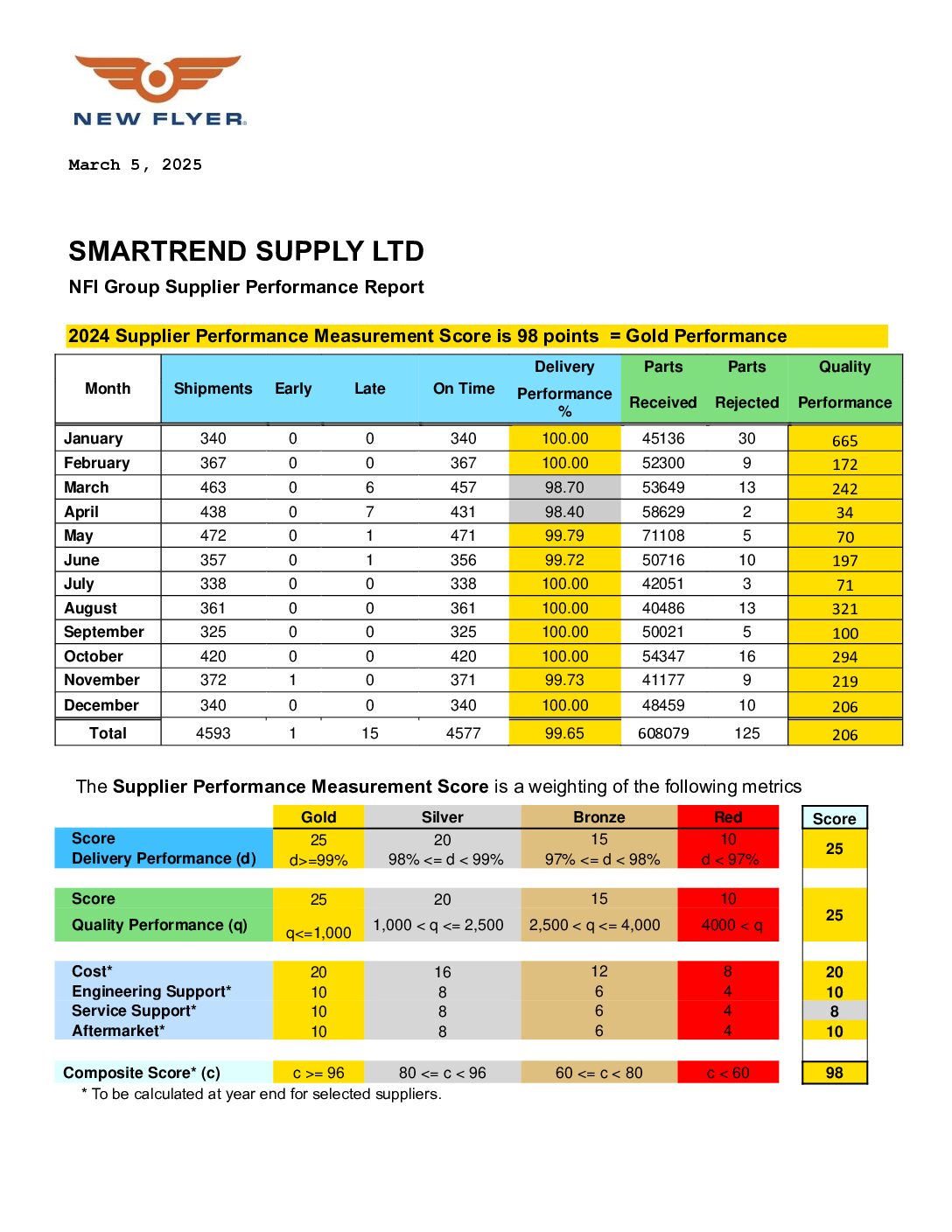

What our customers are saying

FAQ

What is a customer designed part or assembly?

What are your standard payment terms?

What happens if you need to resource a part from one of your partner factories?

Do you subcontract your quality control?

How do labour rates compare in the countries where you manufacture?

Global Labor Rate Comparisons – Read the Reshoring Institute study for more information.

Are you a U.S. or Canadian Company?

How long does it take for you to quote?

Please allow two to three weeks from the time that we have received any required information.